Specialty Support Services

We employ key support services in order to be the most complete roll covering company in the world. These key services allow us to complete our roller and molding orders entirely in house. We have no need to subcontract machine work to an outside vendor or find a secondary source for special requests. These support services ensure that we control every quality aspect as well as prompt delivery to our customers.

Industrial Roller Solutions

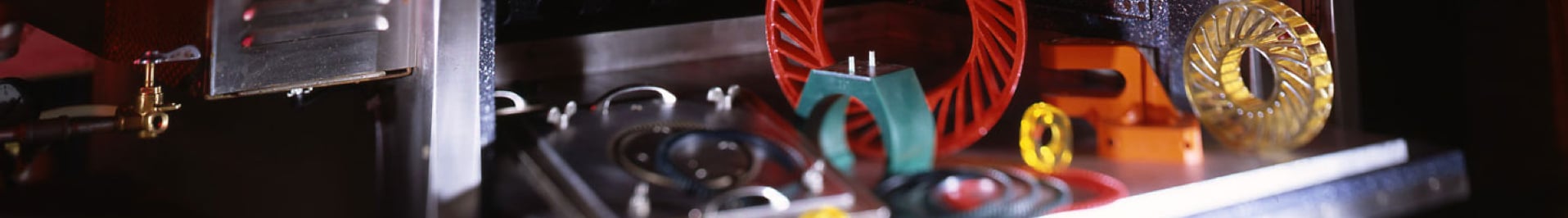

Through our industrial roller services, we provide key related offerings that are all part of the rubber roller and molding spectrum. From our Teflon sleeve systems to our machine shop repairing journals or making molds, our customers have come to expect it all from Rol-Tec. We also have the capability to roll grind all of your metal, chrome, and tungsten rollers.

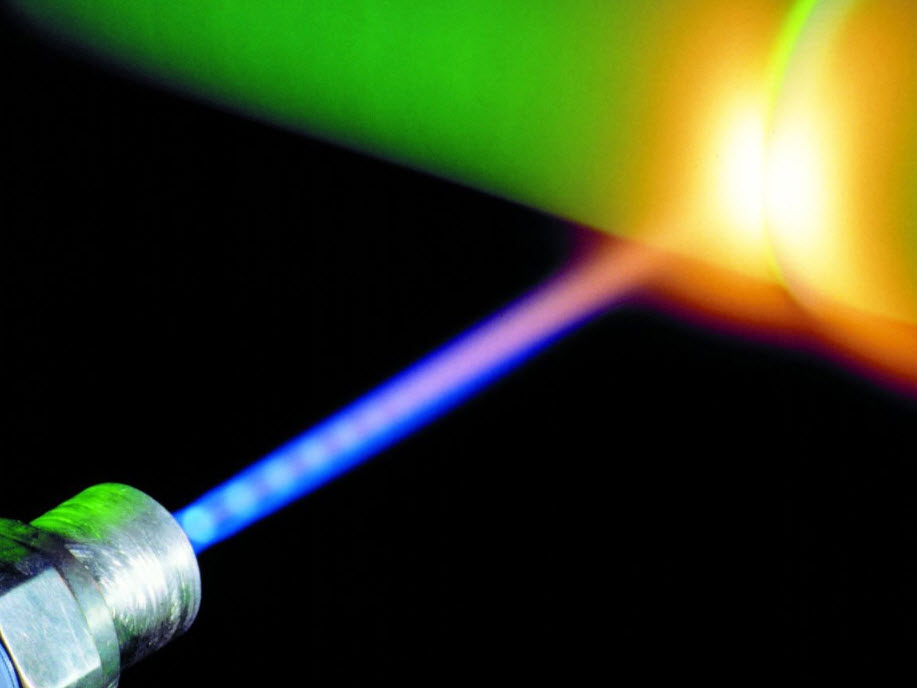

Rol-Tec offers a state-of-the-art laser profiling system to measure final diameter and other critical dimensions for very precise roller applications.

For extreme industrial applications, Teflon shrink sleeves can be applied over rubber or bare metal rollers. Typically, Teflon is employed to either gain release or to protect the rubber from very high heat environments.

In addition to being a trusted supplier of new industrial rollers & cores, Rol-Tec specializes in rubber and urethane roller recovery services.

Rol-Tec has acquired Axis Machine Co.,which means we can now offer in-house precision metal roll grinding in addition to our rubber and urethane roller services.

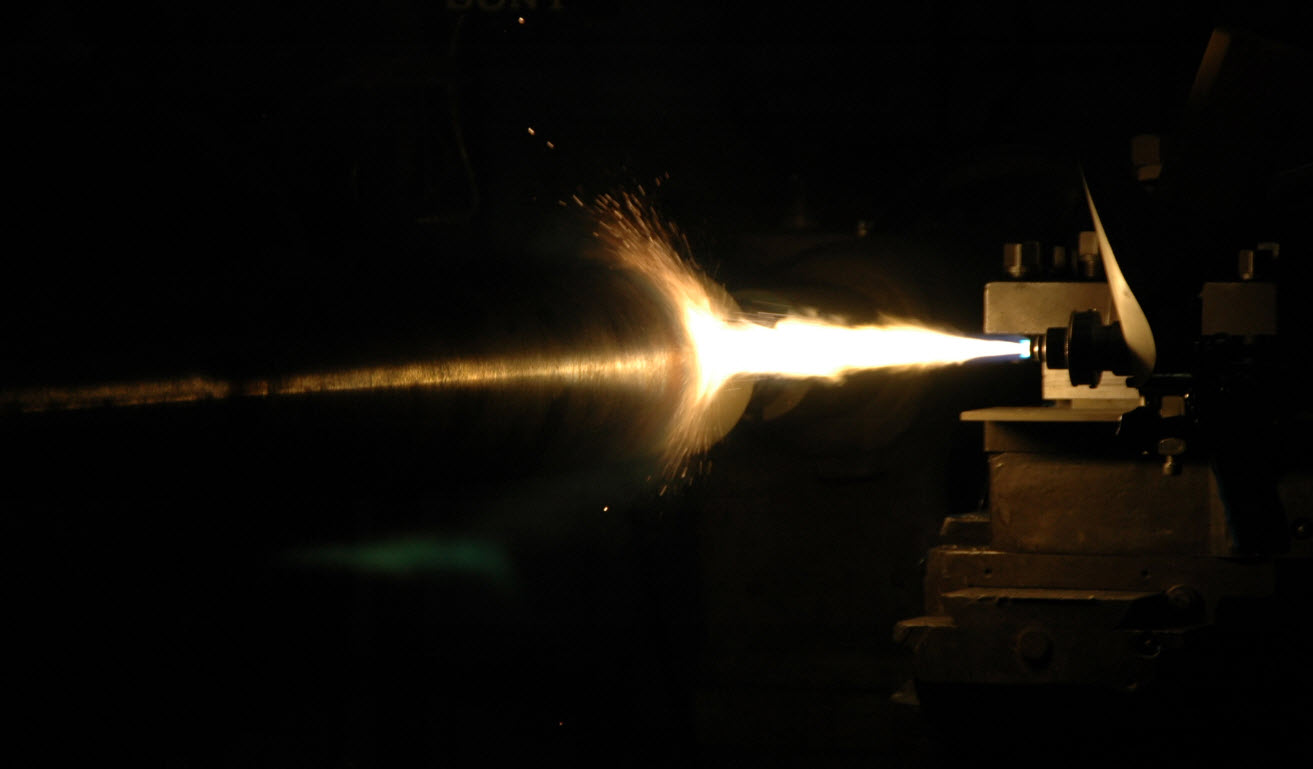

Rol-Tec’s flame spray technology includes tungsten carbide, ceramic, and other extremely durable metalized coatings for the roughest applications.

We employ CNC turning centers, CNC vertical milling centers, CNC/manual hybrid lathes, CNC/manual mills, dynamic roll balancers, as well as a variety of other manual machines.