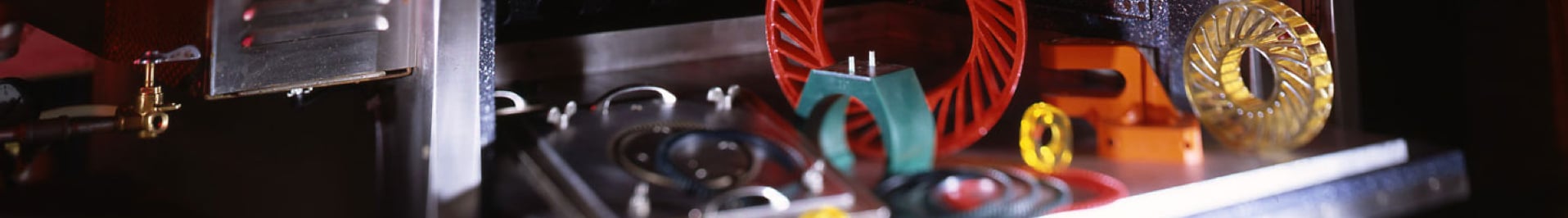

Roller Covering & Molding Materials

We have vetted the best suppliers to provide only the highest quality rubber and urethane materials for our roller coverings and molded precision parts. We have found by using the highest quality elastomers our processing costs are lower while providing the very best roller covering with the physical properties demanded by your engineers.

Rubber compounds are unusual in the physical world because as you improve one characteristic of a compound, you often lose other beneficial qualities. There are no universally perfect elastomeric compounds that possess all the positive physical properties for every application. At Rol-Tec, we recommend the compound that will be the best material for your operation with the correct balance of properties for your roller or part. Heat, pressure, speed, environment, and the chemicals that will make contact with the compound are some of the important pieces of information needed for proper material selection. To recommend the best candidate material for your specific application, we will learn about your operational needs and balance these with the different elastomer qualities of the various compounds and blends.

The correct rubber or urethane formula is selected by comparing the physical properties the elastomer possesses to the desired task the roller is expected to perform. Using the finest quality materials that exhibit the true physical properties needed for your application means we will manufacture a roller or mold a part that will perform properly for a long period of time.

Nitrile Polymer (NBR) Nitrile is a synthetic rubber compound that can be blended to enhance toughness, resilience, oil resistance, and other desirable characteristics.

Chlorosulfonated Polyethylene. Hypalon is very tolerant of solvents and performs well when exposed to corrosive chemicals. It can be blended with Teflon or Silicone to improve release characteristics.

Chloroprene - there are no characteristics to which chloroprene is superior to all other special-purpose rubbers. Its importance is due to a combination of technically essential properties.

Laser Engravable Elastomers - Our special laser compounds are specifically designed for applications ranging from flexographic printing to paper embossing.

HNBR - High heat tolerance and excellent physical properties make HNBR the optimal and sometimes only compound choice in many industrial operations including paper making, embossing, steel manufacturing, and laminating.

Carboxylated Nitrile XNBR - The result of carboxylating the Nitrile is improved abrasion resistance, tear resistance, and tensile strength.

Ethylene Propylene - EPDM rubber compounds were developed to find a rubber material that had better chemical, heat, ozone, UV light and weather resistant characteristics.

NR - Natural rubber is a very tough material that is well-suited for many printing and industrial applications.

Polysiloxane - This high heat tolerance and good release characteristic make silicone the right choice for many laminating and coating operations.

Viton - Fluoroelastomers refer to a family of synthetic rubber compounds specifically designed to have superior resistance to oils, gasses, and chemicals at higher temperatures

Cast Urethane/Polyurethane - A wide range of durometer can be accomplished from 20 Shore A to 70 Shore D as well as different tensile strengths, oil resistance, or compression sets depending upon the urethane formulation.

Custom Compounds - specialty rubber products for the more uncommon applications or demands such as Teflon, FDA & Anti-static rollers